I have not posted on this blog for month's. I recently noticed that my website has seen a fair share of traffic as a result of referrals from this blog. So evidently I need to update this blog more frequently and perhaps provide my in site on some valuable information on frame building, fitting, and training. I will do my best. Any suggestions on topic's would be appreciated.

So what have I been doing since August? Good question. Mostly trying to survive another Idaho winter. But on the cycling side of things, I have been busy building frames, training, and recently taking the test to become an USCF certified coach.

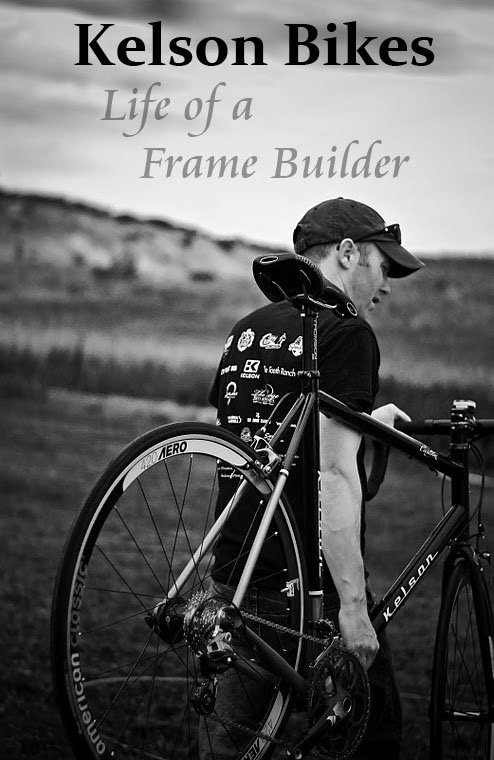

Frame building has been going quite well. I am staying busy with a lot of repeat customers. Building frames for there family, and updating there first generation steel Kelson's with some new titanium frames. I have become quite comfortable with my titanium road frame building. And have recently experimented with a 650b mountain bike. It turned out great! I had a customer who wanted a hard tail that was a little different. So why not a 650b. For those of you who do not know what a 650b is. It is the tire size between 26" and 29". It works well for shorter riders who would like to join the big wheel revolution. A little smoother than a 26" hard tail yet spins up quicker than a 29". Might be just the ticket. I am currently getting ready to put out a batch of steel frames. I have invested some time into selecting some quality tubing, filler rod, and various dropouts and small parts that will step up my game in the steel market. I have a strong passion for steel frames I love how they ride and I feel that they really can be a superior material for women and riders who are looking for a particular ride characteristic in a frame.

Now for the big news. Many of you may not know that I have had a fair share of experience with composites. I use to build carbon fiber Kayak's and was involved building drift boats. So it only seems logical that I combine my knowledge of frame building with composite manufacturing and build some custom carbon bikes. I have invested significant time and money into developing my own process for building a tube to tube custom carbon bike. Many people have contributed. Edge Composites will be supplying the tubing. Paragon machine works has provided all the bonded Titanium parts ( head tube inserts, bottom bracket, dropouts). I am waiting on just a few minor details with the molds and then we will be able to produce our first prototype for testing. I have tested a few joints at home and have been very pleasantly surprised by the results. My wife is a little tired of me cooking carbon fiber in the oven. So it looks as if I will be purchasing a curing oven hear real soon. I will keep you updated on the progress and will clue you in real soon on the whole process.

Thanks for looking, Brian